Matco Tools (Mt2769) 1/2 Drive Compisite Air Impact Wrench Review

Eugene is a trained engineer and self-taught domicile improvement enthusiast with almost 40 years of professional and DIY experience.

Air drill.

© Eugene Brennan

Air tools as the name suggests are tools powered by compressed air, different conventional power tools which are either powered by a bombardment or a 120/240 volt mains supply. This article outlines the basics of how they piece of work, what tools are available, and how to apply them with an air compressor.

If you find this guide useful, delight take the fourth dimension to share it on social media using the buttons on the top of the page.

Glossary of Terminology Used With Compressed Air Systems

- CFM or Cubic Feet / Minute The quantity of compressed air which an air compressor can supply or which an air tool requires

- Pressure Air is compressed or "squashed" inside a compressor into a fraction of it'south original volume. Air is stored in a tank. The pressure of the air is measured in bar, pounds per square inch (PSI) or kilopascals. 1 bar = xiv.v psi = 100,000 pascals or 100 kPa

- Pneumatics This refers to using compressed or pressurized air

- BSP Thread British Standard pipe thread. Fifty-fifty in countries which use the metric system, the imperial-based BSP standard is used (Except in the U.Southward.)

- NPT Thread National Pipage Thread. An inch based thread used in the U.S.

- Cuff (Gauge in U.k.) In the context of air tools, this refers to the size of a fitting or internal bore of a hose

What is an Air Compressor and Compressed Air?

An air compressor is a device that squeezes air into a fraction of its original volume, so that information technology takes upwards about eight to 10 times less space. When air is reduced in volume, pressure increases proportionally. So if volume is eight times smaller, pressure is viii times higher. This is described by Boyle'south Law:

"At constant temperature, the pressure of an platonic gas is inversely proportional to the volume"

or

PV = constant

Boyle's Law - At constant temperature, as book decreases, pressure increases and vice versa

Public domain via Wikimedia Eatables

How Compressed Air Works

Most workshop compressors are reciprocating types, and so they use a piston and cylinder organization, driven by an electric motor or engine to shrink air. As the air is compressed, information technology's fed to a storage tank which acts as a reservoir. The tank tin deliver a big pulse of compressed air as needed, potentially greater than the pump could deliver on its own.

Basically, the same tools as are bachelor in battery or mains powered versions....and some others.

Coil to Continue

Read More than From Dengarden

Some examples:

- Drills

- Sanders

- Angle grinders

- Saws

- Boom guns

- Chipping hammers

- Spray guns

- Tire inflators

- Air ratchet

- Impact wrench

Other tools which aren't ordinarily bachelor in electric versions are:

- Air gun

- Sand blasting gun

- Needle scaler

- They have a loftier power-to-weight ratio. In other words, an air tool will be lighter than a cordless or mains powered tool of the same power rating. Air tools accept unproblematic air motors or pistons which are lighter than an electrical motor. This is important for associates workers who may be using a tool all twenty-four hour period, and obviously a lighter tool will lessen fatigue

- They are simpler and have less working parts than an electric tool, so there is less to become wrong

- An air tool can be stalled indefinitely. If you stall an electric tool, the back EMF(Electro Motive Force) drops to aught and current flowing through the motor becomes very large. If the trigger on the tool isn't released immediately, the motor tin rapidly burn out

- Unlike electric tools which have a universal motor (it tin can run on AC or DC) which produces sparks at the brushes in contact with the commutator, an air tool is spark-less. This tin exist a distinct reward in chancy environments where there may exist gas or flammable liquids

- There is no electrocution risk in damp environments

- Tools are quite slim compared to electric tools with bulky motors. So they can exist used in cramped locations (e.yard. working on cars)

Yeah they practise. Yet, depending on the application or environs, the advantages may outweigh the disadvantages.

Some disadvantages:

- An air hose is required to supply air to the ability the tool. This is ordinarily thicker, heavier and less flexible than the power cord of an electric tool. Even so coiled air hoses are bachelor which may be more convenient e.m. for low powered bench tools

- An air compressor is required, calculation to the cost of the organization

- Air fed to a tool must be filtered and lubricated to prevent premature wear. If a tool is used infrequently, it can be lubricated with a few drops of oil dropped into the intake port

- Air tools tin can exist somewhat noisy as air exits the exhaust port on the tool

- They are usually more expensive than their electric counterparts

So as y'all can meet, there are advantages and disadvantages to using air tools and at that place is a time and place for using either a cordless battery tool, a mains powered tool or an air tool. It is not a instance of "either or".

What is Required to Build an Air System in a Workshop?

- An Air Compressor. This compresses the air and stores it in a tank. Various types / sizes / capacities are bachelor. The important things to consider when buying are the horsepower of the compressor (HP), the commitment charge per unit in cubic anxiety per minute (cufm) or liters per minute, the tank capacity in gallons or liters and whether the compressor is electric or gas-powered. The delivery rate of the compressor should match the flow charge per unit demand of the tool. If information technology doesn't, you will have to wait every and so frequently for the tank to fill and pressure to build before using your tool again. For tools with a depression duty cycle (only used for a few seconds with long pauses in between) east.g. nailers, this isn't an event. Withal if y'all're using a blower, angle grinder etc, the tank can apace drain.

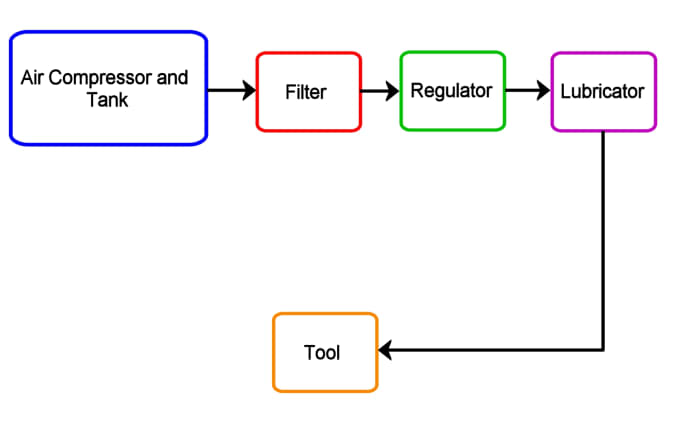

- A Filter / Regulator / Lubricator. A filter removes dust and water from air. Dust can scour and damage the working parts of tools, eventually clogging everything up, but more importantly it volition cause wear and desperately sealing surfaces. When air is compressed, water will condense out (the corporeality depending on ambience humidity). This h2o may cause corrosion within tools if it isn't removed by the filter.

A regulator is similar a faucet, controlling the pressure of the air, allowing it to exist turned upwardly and down, depending on the maximum requirements of the tool and also the application. A skillful quality regulator should keep the pressure level constant, independent of the air demand of the tool.

A lubricator creates a mist of tiny oil droplets in the air flow, which lubricate moving surfaces in contact inside the tool. When spray painting, obviously lubrication is not necessary and would spoil a finish. For infrequent, brusk and occasional use, a lubricator is non necessary and a tool tin be lubricated with a few drops of oil dropped into the intake port.

A regulator, filter and lubricator can be bought every bit a single unit, or the modules tin can be plumbed individually together in various combinations. Sometimes the regulator/filter may exist provided with and fastened to the air compressor.

You tin dispense with all this stuff and just use air straight from the compressor. Nonetheless water and grit will shorten the life of your tools if you lot are using them regularly. Tools too accept a max pressure rating which can be less than the typical 8 bar / 120 PSI output pressure rating of a compressor. Overpressure could crusade harm to a tool, or worse still, rupture. A regulator will drop the pressure level to a safe value. - An Air Hose. 1 hose is required to connect the compressor to the filter/regulator/lubricator. You then need a work hose to connect to your tool. Various options are available. You lot can buy a coiled hose (similar the coiled cord on a telephone handset), or a not-coiled hose. Hoses are unremarkably fabricated from rubber or plastic. Plastic is quite rigid and can crack over time. Condom is more flexible. Air hoses have various internal diameters. This becomes an result if you are using a tool which uses a lot of air. A hose with a small internal bore will crusade a pressure level drop and less power will be available to the tool. A very long hose will besides have the same issue, dropping pressure. This is analogous to an electrical extension string dropping voltage if it is of inadequate gage or too long when powering a loftier powered tool which requires high current

- Air Tool. The tool will have a cubic anxiety / minute (CFM) rating. The air compressor should be cable of supplying this flow rate

Air compressor arrangement diagram.

© Eugene Brennan

Filter Regulator Lubricator Unit of measurement (FRL)

Filter, regulator, lubricator unit. The filter has an automatic drain for releasing water when pressure is released

© Eugene Brennan

While your compressor will usually be set at a pressure of typically 8 to 10 bar past the pressure cut-out switch (This should be checked so that it's at the recommended setting and lower than the max rating), your tool may have a max force per unit area rating lower than this. The pressure will be printed on a label on the tool or you can check the printed manual or search for information technology online. Gear up your regulator to conform.

Safety Relief Valves on Air Compressors

This vents pressure when information technology becomes excessive if the automatic pressure cutting-off valve fails or its pressure is set too high. You lot should check this regularly to make sure information technology is operating and not seized. Often these have a keyring type pull for releasing pressure level.

Safety relief valve. The ring is pulled to release pressure (Wear muffs and safe glasses when checking)

© Eugene Brennan

Diverse types of air tools

Air Shears

Air shears for cut sheet metallic

© Eugene Brennan

Cutting caput of air shears

© Eugene Brennan

Compressed Air Smash Gun

Framing nailer for light gage nailing of timber

© Eugene Brennan

Air Drill

Air drill.

© Eugene Brennan

Air drill with coiled air hose.

© Eugene Brennan

Air Tire Inflator

Tire inflator.

© Eugene Brennan

Air Blowgun

Air blow gun which can be used for blowing away grit, water, drying etc.

© Eugene Brennan

Quick release push button fit connectors on an air hose and air tool.The male part is generally called a "bayonet" and the female role a "coupling". Air hoses tin also be permanently attached to tools using screwed fittings.

© Eugene Brennan

Sealing an Air Fitting: BSP and NPT Threads

Internationally, air fittings follow the BSP (British Standard Pipage) standard. In the U.S., the NPT (National Piping Thread) standard is used. Both standards are based on inch measurements rather than metric. NPT and BSP threads differ in profile, bore for a specific size thread, and pitch. So they are incompatible. It may be possible to mate threads of both types but they may non seal very well, however adapters are available. A pipe thread size refers not to the external diameter of the threads, simply originally referred to the internal bore of a steel pipe for which the thread was intended.

Low ability tools mostly accept a ane/4 inch BSP or NPT female port into which a quick-release adaptor can be screwed. High power tools such as touch wrenches used to remove bolts from truck wheels unremarkably take larger 3/8 or 1/2 inch ports. Fittings may take tapered threads which get wedged as they tighten, forming a skilful seal. Air fittings tin can be sealed using teflon (PTFE) tape. The record should be wound clockwise looking from the entry point of the fitting. Apply a few layers to grade a tight seal.

Links to the BSP and NPT standards on Wikipedia:

NPT threads

BSP threads

This tool was supplied with a 1/4 inch BSP male person coupler / nipple which was glued into place. I could have used it with a hose with a female screw plumbing equipment on the terminate, however I wanted it to be quick release so I could hands remove it from the hose rather than having it permanently screwed on.

This detail tool was supplied with a 1/4 inch BSP male coupler / nipple which was glued into place. It requires a female quick fitting adaptor to be attached. (Alternatively the nipple could have been replaced with an adaptor with a male thread)

© Eugene Brennan

Wind the PTFE tape tightly in a clockwise management downwards the length of the threads. Apply a few layers of tape

© Eugene Brennan

PTFE tape on threads.

© Eugene Brennan

one/4 inch BSP quick release bayonet adaptor with female person threads.

© Eugene Brennan

Screw the adaptor onto the tool.

© Eugene Brennan

Alternative Fittings

I could have replaced the nipple in the tool with these adaptors

Two different types of male bayonet adaptors. The one on the left is recommended every bit information technology has a larger internal diameter and results in less pressure driblet when used with tools that require a high flow rate.

© Eugene Brennan

How to Fit a Connector to a Hose

Plumbing fixtures a barbed, quick release adapter to a hose. This fitting plugs into the outlet coupler of an air compressor (or the coupler on the end of another hose if you want to get more range)

Barbed fittings are necessary when connecting to hoses (Off the shelf, made upwards hoses volition generally accept fittings permanently crimped onto the stop of the hose)

© Eugene Brennan

Cut the terminate of the hose square. This useful tool for cutting hoses and lite pvc tubing is fitted with a widely available "Stanley" type knife blade

© Eugene Brennan

Slide a hose clip onto the hose, and push button the adaptor on. Some soapy water may help to lubricate surfaces if the adaptor is a tight fit

© Eugene Brennan

Button the clip then that it lies halfway forth the affront, and tighten with a screwdriver.

© Eugene Brennan

Reading an Air Gage (Gauge)

The scale on an air gage is marked in bar, PSI, kPa or a combination of the measurement systems

Air Gage

The blue scale is bar, the outer scale is PSI, the green scale is kPa.

© Eugene Brennan

Air tools such as nail guns utilize a piston and cylinder arrangement simply like in an internal combustion engine. Air force per unit area acting on the large surface area of a piston accelerates it rapidly until it collides with a smash head, driving it forward. Tools such as drills have a rotary air motor. Air pressure interim on the surfaces of the motor give it torque and cause information technology to turn. Air hammers take a double acting piston which is rapidly moved backwards and forrard equally air valves rapidly modify the side of the piston which the air acts on

Why Is There Water in the Air Compressor Tank?

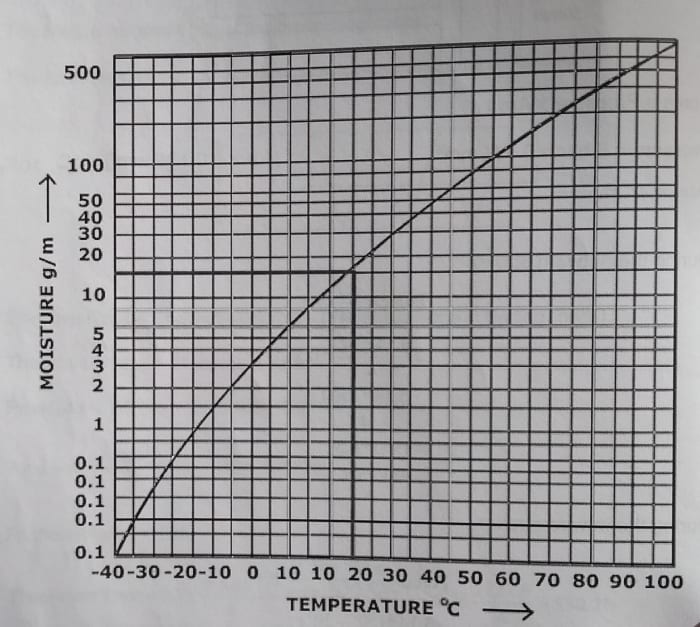

This happens naturally as air is compressed. Air can only hold a certain corporeality of water at a given temperature before information technology starts to condense out. Relativity humidity (RH) is divers as the corporeality of water vapour in air as a percentage of the maximum amount of water that air tin hold at a specific temperature. And then 100% RH means air is saturated and 0% RH means it is totally dry out. As temperature increases, air can hold more than water per unit volume and vice versa. When air is compressed, it takes up less infinite, and considering at that place is a limit to the amount of h2o a certain volume tin can hold, it will somewhen condense out if book is reduced sufficiently. Water vapour density in the metric system is usually specified in g/yard3.

Example:

2 cubic metres of air at 20° C is at a h2o vapour density of 7 g/m3. (fifty% RH at this temperature) The air is compressed by a factor of 10 and allowed to cool back to twenty deg C. How much water condenses out?

Respond:

The amount of water in the original air is 2 m3 x 7 g/m3 = 14g

When it is compressed, the new volume is ii/ten = 0.2 mthree

At 20 deg C, the max amount of water the air can hold is 15 g/yard3 (run into graph beneath)

Simply 0.2 chiliad3 can only agree 0.2 ten 15 grand/g3 = 3g. So the amount of h2o that condenses out and collects in the air tank is 14 - 3 = 11g

Dew point curve.

© Eugene Brennan

- Habiliment goggles when using tools which tin throw up debris east.m. air grinders, air blow guns and air chisels

- De-pressurise hoses before connecting / disconnecting from tools and compressor

- Don't let compressed air to blow onto pare or an open wound (This tin can potentially cause "the bends")

Tool and Compressor Maintenance

- Drain water from a compressor every fourth dimension information technology is used

- Cheque oil level regularly and change oil at intervals equally specified past manufacturers recommendations

- Lubricate tools before utilise by dropping oil into air entry port of tool or use a lubricator. Make clean and lubricate moving parts of tools

Power Craft is the registered trade mark of Aldi GmbH & Co. KG

Aldi in no style endorses this article.

This commodity is accurate and true to the best of the author's noesis. Content is for informational or entertainment purposes simply and does non substitute for personal counsel or professional advice in business organization, financial, legal, or technical matters.

Questions & Answers

Question: What blazon of compressor should be used for air sander works like motorcar or wood?

Answer: You would need to cheque the spec on the tool for the required cubic feet per minute need (CFM), then buy a compressor to arrange. The problem with using a tool like a sander is that it draws air continuously different a blast gun, rivet gun, etc that just takes a pulse of air. So information technology needs a compressor that can deliver a lot of air continuously or a large tank or both if the sander is going to be used for minutes at a time. Typically a sander will take 2.5 to 5 CFM of air.

© 2014 Eugene Brennan

Joanna on February 25, 2019:

Cheers for this. I needed some quick useful data and you went above and beyond. Very well written!!

Nube Airtool User on January 04, 2018:

Good commodity, especially on describing use of the filter/regulator/lubricator.

portable air compressor reviews on Baronial 31, 2017:

Information technology is a dainty blog.And also informative and of import web log.When I read this really I like it.

Instronline on September 10, 2015:

Cheers for sharing this information.This is existent not bad information about air filter ,regulator and lubricant control.This will help us to improve quality of our tools.

Eugene Brennan (author) from Ireland on March 05, 2014:

Thank you for the comments - Hopefully it will help someone out in that location!........

Writer Flim-flam from the wadi near the niggling river on March 04, 2014:

Fantastic article! You are a real expert in ability tool engineering. Enjoyed and voted upwards!

Source: https://dengarden.com/home-improvement/What-Are-Air-Tools-Used-For

0 Response to "Matco Tools (Mt2769) 1/2 Drive Compisite Air Impact Wrench Review"

Post a Comment